ET-PP Industry Contact

Join the forefront of innovation.

Get Involved

Contact the ETPP Industry liaisons atet-info@ifae.es and explore partnership opportunities.

Learn More

Download the ET Industry Brochure and discover how your industry can play a role in shaping the future of gravitational wave detection.

The Einstein Telescope:

A FUTURE GRAVITATIONAL-WAVE OBSERVATORY

The Einstein Telescope (ET) is a proposed third-generation gravitational-wave (GW) observatory, poised to revolutionise our comprehension of the universe and the fundamentals of gravity. Designed as an advanced underground facility, ET aims to enhance and expand upon the successes of second-generation laser-interferometric detectors such as Advanced Virgo and Advanced LIGO. To achieve its goals ET requires intense developments which are currently being carried out by a large international collaboration.

HOW IT WORKS

The operating principle of ET, like that of Virgo and LIGO, is based on interferometry. Laser beams travel through long vacuum tubes in different directions, running back and forth until they recombine and generate an interference pattern on an output screen. This method allows ET to measure with unprecedented accuracy the infinitesimal variations in the distances travelled by light inside the vacuum pipes as gravitational waves pass by (less than a billionth of a billionth of a metre). Consequently, it will detect ripples in spacetime caused by accelerating massive objects, such as merging black holes, millions or even billions of light-years from Earth, ultimately allowing us to better understand the origin of the Universe itself, the Big Bang.

SCIENCE & INDUSTRY

Industry involvement is of paramount importance to the success of this ambitious project. It plays an essential role in driving technological advancement beyond the current state of the art, while providing the timely expertise needed to optimise production processes and reduce costs.

Outlined below are the key technologies currently developing for ET:

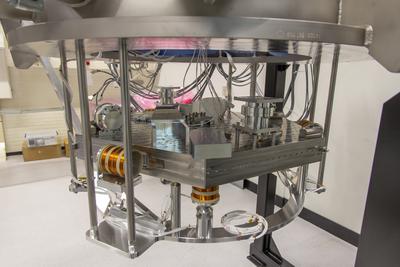

1. SENSORS AND PRECISION MECHANICS

Everything in the external environment can disrupt the detection of GW signals. To isolate the experiment as much as possible, a massive ultra-high vacuum system will be required, as well as seismic motion attenuators for core optics, mode cleaners, benches, and mirrors. Additionally, inertial sensors will measure earthly vibrations so they can be digitally excluded from readouts. Moreover, the photosensitive diodes that capture the laser interference signal will operate in cryogenic vacuum conditions to ensure high sensitivity.

2. OPTICS & OPTICAL METROLOGY

ET will rely on the precise measurement of relative length differences in kilometre-scale arms of a laser interferometer. Key optical components include super-polished mirrors with optimised coatings, an ultra-stable laser producing monochromatic beams, and additional systems for instrument control and stabilisation. Detection of the GW hinges on minute ‘flickers’ in the photodetector output, so ET requires low round-trip losses of below 50 ppm to achieve several hundred kW of laser power, minimal wave-front distortions, and low amplitude and phase noise with stable pointing accuracy. Improving the quality of mirror coatings to reduce optical losses is an area where industry expertise in advanced materials and precision manufacturing is crucial.

3. VACUUM SYSTEM

ET will be a massive UHV vacuum system (about 10–10 mbar pressure) featuring around 130 km of 1-metre diameter pipes, ensuring undisturbed laser beams between mirrors suspended to dampen vibrations and housed in 10-20 m high, 3-5 m diameter towers. Industries specialising in vacuum technology, such as those involved in accelerator or space applications, could provide innovative solutions for more robust and efficient vacuum systems.

4. LASERS

The laser source for ET requires extreme precision at a wavelength of approximately 2090 nm. Commercially available lasers need to be improved to achieve the linewidths and stabilities sufficient for ET. Additionally, the implementation of quantum technologies, such as squeezed light sources, could be enhanced through collaboration with the photonics industry.

5. ADVANCED CONTROL ALGORITHMS

ET requires advanced control systems to manage its thousands of signals and maintain the interferometers at optimal performance. Current interferometers are limited by control-generated noise at low frequencies. New algorithms, including AI methods, are crucial to overcoming this limitation.

6. CIVIL ENGINEERING, SIMULATION, AND MODELLING

Advancements in numerical modelling software and virtual/augmented reality have revolutionised the computation and visualisation of processes like ground motions, which are challenging to observe due to their interaction with infrastructure. The growth of Building Information Modeling (BIM) in civil engineering has enhanced monitoring during construction, safety inspections, and real-time updates on project impact from unforeseen events.

7. VIBRATION-FREE CRYOGENICS COOLING

ET will feature core optics operating at a temperature of 10 Kelvin. The 200 kg mass mirrors are suspended by very thin wires. After the initial cooldown, the operating temperature of the mirrors must be maintained solely through radiation and conduction via very low-stiffness thermal straps (heat links) to ensure that the telescope’s performance is not affected by vibrations from the cryogenic plant. In this scenario, companies involved in cryogenics and advanced cooling technologies could help develop ultralow noise cryocoolers and active vibration isolators compatible with the UHV low-temperature environment.

8. DATA HANDLING AND PROCESSING

The vast amounts of data generated by ET will require sophisticated data processing and storage solutions. Collaboration with tech companies specialising in big data, cloud computing, and AI could lead to more efficient data management and analysis tools.

Images by Nikhef